In modern industry, hydraulic motors and electric motors are two of the most commonly used drive systems. They both play important roles in many applications, but their operating principles, efficiency, application areas, and maintenance requirements differ significantly.

1. Working Principle Comparison

Hydraulic Motors

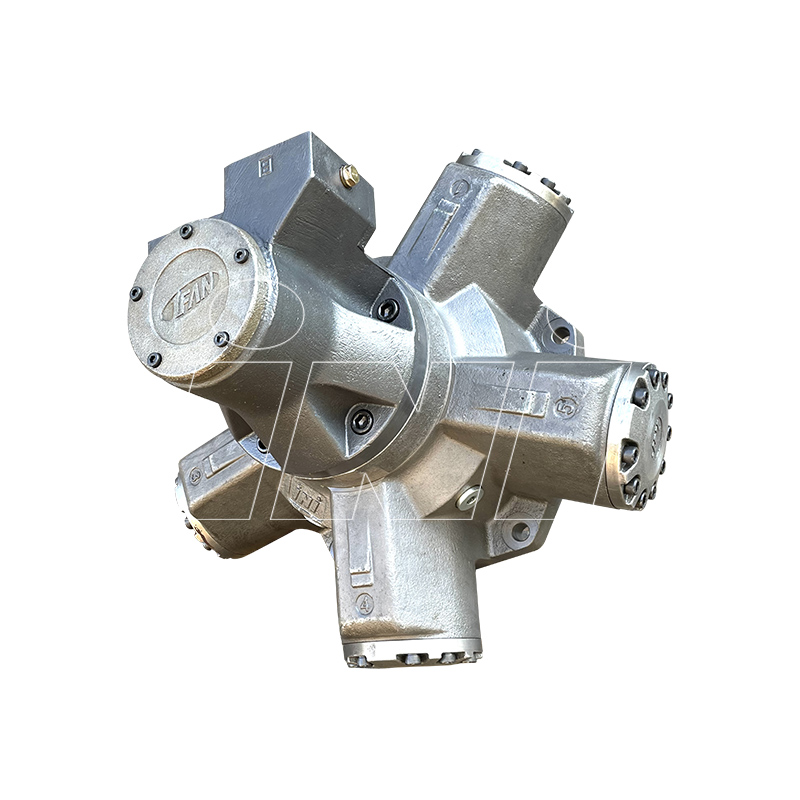

Hydraulic motors work based on hydraulic pressure. The hydraulic system pumps hydraulic oil into the motor, where the pressure generated by the oil drives the rotor or blades to rotate, producing mechanical power. Hydraulic motors can provide high starting torque, making them ideal for applications requiring high load and low-speed, high-torque performance. Hydraulic systems can transmit power very efficiently, making them suitable for high-power applications.

Electric Motors

Electric motors work by converting electrical energy into mechanical energy. Through electromagnetic interaction between the stator and rotor, electric motors generate rotational force. Electric motors are known for their high operational efficiency, especially under high-speed and stable load conditions. The working principle of electric motors is relatively simple, and they typically offer more precise speed control, making them suitable for applications requiring high speed and precise adjustments.

2. Power Output and Efficiency

Hydraulic Motors

One of the significant advantages of hydraulic motors is their ability to provide high torque, especially at startup. Hydraulic motors can deliver very high output power at low speeds, making them suitable for applications requiring high torque, such as heavy machinery, mining equipment, and construction machinery. Hydraulic systems can efficiently transfer energy, so in high-load applications, hydraulic motors can maintain high operational efficiency. However, the efficiency of the hydraulic system is affected by the quality of the hydraulic oil and the design of the pipeline system. Over time, contamination of the oil may reduce overall efficiency.

Electric Motors

Electric motors have very high efficiency, especially under stable load conditions. They are commonly used in equipment requiring high-speed operation and stable load, such as automation production lines, robotics, and small machinery. Modern electric motors have seen significant efficiency improvements and are excellent at balancing high-speed operation and high-efficiency performance. Electric motors are typically more energy-efficient over long-term operation as they generate less heat and can maintain sustained performance.

3. Application Scenarios

Hydraulic Motors

Hydraulic motors are widely used in industrial environments that require high power output and high torque. They excel in low-speed, high-torque applications, and common uses include:

- Construction machinery: Excavators, bulldozers, etc.

- Mining equipment: Hydraulic motors provide reliable power in harsh underground environments.

- Marine applications: Used in equipment like cranes and rudders where high torque is needed.

The advantage of hydraulic motors lies in their ability to provide powerful output in a compact size, making them ideal for high-load and low-speed operation.

Electric Motors

Electric motors are more commonly used in applications requiring high speed and precise control. They are suitable for:

- Automation production lines: Electric motors offer stable power and are easy to control for speed adjustments.

- Robotics: Electric motors are perfect for precise control, particularly in fields requiring fast response and accurate movement.

- Household appliances: From air conditioners to washing machines, electric motors are ubiquitous.

- Wind power generators: Modern wind turbines rely on electric motors to convert mechanical energy into electricity.

Electric motors are perfect for applications that need precise speed and torque control, especially in environments that require high efficiency and long-term operation.

4. Maintenance Costs and Lifespan

Hydraulic Motors

Hydraulic motors generally have higher maintenance costs. Hydraulic oil needs to be regularly replaced, and the seals and piping in the motor system may wear out or leak over time. Additionally, the hydraulic pump and motor components require frequent inspection and servicing to maintain efficient operation. If the system is not maintained regularly, the oil may become contaminated, reducing efficiency and even causing system failures. Therefore, hydraulic motors require more maintenance than electric motors.

Electric Motors

Compared to hydraulic motors, electric motors are less costly to maintain. Most electric motors only require periodic checks of electrical connections, cleaning of fans, and lubrication of bearings. The components of electric motors are relatively simple, resulting in fewer failures, and they generally have a longer lifespan. Electric motors typically have lower repair and maintenance costs, making them a more economical choice in many applications.

5. Installation Space and Environmental Adaptability

Hydraulic Motors

Hydraulic motor systems typically require more space for components such as hydraulic pumps, oil tanks, piping, and valves. As a result, they are more suitable for applications where space is less of a concern. Hydraulic systems are more sensitive to environmental conditions, particularly temperature and humidity, and may require additional protective measures. Moreover, there is a risk of oil leakage, which could contaminate the working environment, especially in precision equipment.

Electric Motors

Electric motors occupy less space, making them suitable for applications where space is limited. They also have better environmental adaptability and can operate in a wider range of conditions. Electric motors are not as affected by external environmental factors as hydraulic motors, and they can work efficiently in varying temperatures and humidity. Additionally, they do not require the use of hydraulic oils, eliminating the risk of oil leaks and contamination.

6. Cost Comparison

Hydraulic Motors

Hydraulic motors tend to have higher initial costs, as the hydraulic system requires more components, such as pumps, oil tanks, piping, and valves. This results in higher installation and maintenance costs. However, hydraulic motors provide powerful performance, making them cost-effective for heavy machinery and high-load applications. For these types of applications, the increased upfront cost is often justified by the motor’s superior power and torque capabilities.

Electric Motors

Electric motors usually have a lower initial cost, especially for smaller and medium-sized equipment. The components of electric motors are simpler, and installation and maintenance costs are also lower. As technology has advanced, modern electric motors have become more cost-effective, making them a more economical choice for many industrial applications.

7. Environmental Friendliness

Hydraulic Motors

Although hydraulic motors offer powerful performance, they use hydraulic oil, which poses the risk of leaks and environmental contamination. If hydraulic oil leaks into the environment, it can cause damage to both the machinery and the surrounding area. Therefore, hydraulic systems require careful management of hydraulic oil and must follow strict environmental guidelines. In industries with high environmental protection requirements, hydraulic systems may not be ideal.

Electric Motors

Electric motors do not use hydraulic oil, making them more environmentally friendly. Additionally, modern electric motors have adopted more eco-friendly materials and technologies, reducing their environmental impact. In industries where environmental considerations are critical, electric motors are a more attractive option.

Summary Comparison Table

| Factor | Hydraulic Motor | Electric Motor |

|---|---|---|

| Working Principle | Hydraulic oil drives the rotor to rotate | Electric current and magnetic fields generate rotational force |

| Power Output and Efficiency | High torque, low-speed, high-power output | High efficiency, suitable for stable loads and high-speed operation |

| Application Scenarios | Heavy machinery, construction equipment, mining equipment | Automation equipment, robotics, household appliances |

| Maintenance Costs | Higher, requires frequent oil changes and inspections | Lower, simple maintenance requirements |

| Installation Space | Requires more space for hydraulic components | Occupies less space |

| Environmental Adaptability | Sensitive to environmental conditions | Can operate in a wide range of environments |

| Cost | Higher initial investment | Lower initial investment |

| Environmental Friendliness | Risk of oil leakage and environmental contamination | No oil leakage, more eco-friendly |

ENG

ENG

English

English русский

русский Español

Español

English

English русский

русский Español

Español

TOP

TOP