Introduction

Hydraulic motors are widely used in modern industry, offering not only high-efficiency power output but also precise control in various equipment. Whether in automated production lines or heavy machinery, hydraulic motors play a crucial role. With advancements in industrial technology, the design and application of hydraulic motors are becoming more precise, and their performance continues to improve.

1. Basic Working Principles of Hydraulic Motors

A hydraulic motor is a device that uses fluid (usually hydraulic oil) to drive mechanical movement. Unlike hydraulic pumps, the primary task of a hydraulic motor is to convert hydraulic energy into mechanical energy, driving mechanical components to rotate or move in a linear fashion. Hydraulic motors are widely used in applications that require high power drives, especially in situations where high torque output and low-speed, stable operation are needed.

Working Principle of Hydraulic Motors

Hydraulic motors work by using hydraulic oil to generate mechanical energy. The oil flows through the hydraulic system, and the pressure applied to the internal components (such as blades or pistons) drives them to rotate. The output shaft of the motor is then driven by this motion.

The working principle can be explained in the following simple steps:

- Hydraulic Oil Enters the Motor: The hydraulic oil enters the motor through a pipe, and the flow is controlled by a valve.

- Drive Rotation: The pressure of the hydraulic oil pushes the motor’s internal pistons or gears, causing the motor’s output shaft to rotate.

- Power Output: The rotation of the motor drives the mechanical device or component, providing continuous power.

Types of Hydraulic Motors

There are several types of hydraulic motors based on structure and working method:

- Axial Piston Hydraulic Motors: These motors use pistons moving along the axis to generate power. They are commonly used in applications that require high torque and low-speed operations.

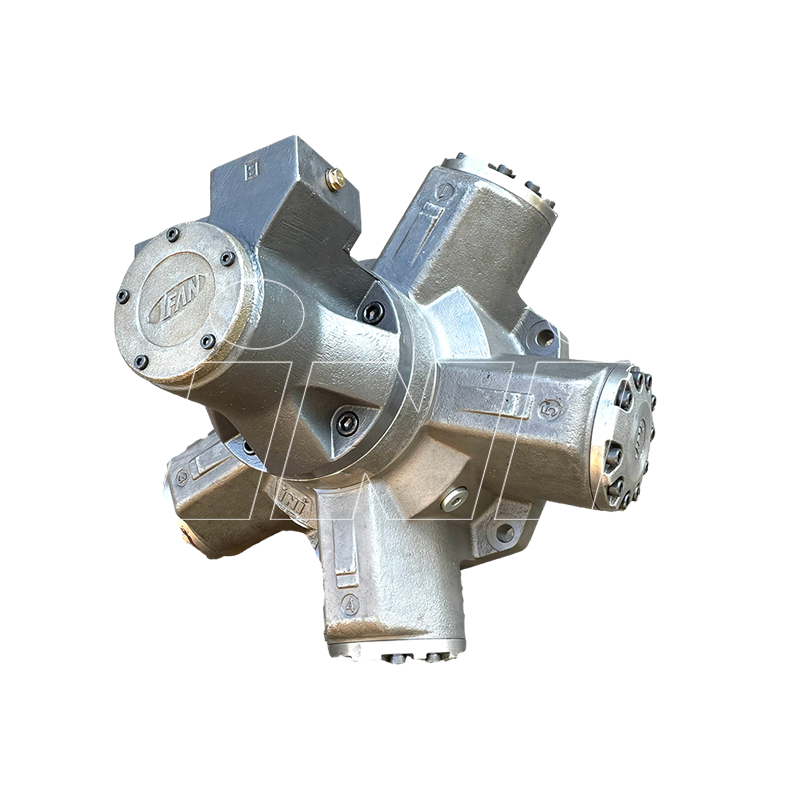

- Radial Piston Hydraulic Motors: These motors use pistons moving radially to generate power, offering high efficiency and stability.

- Gear Hydraulic Motors: These motors have a simple structure and are suitable for medium-to-low load applications, commonly used in general industrial machinery.

| Type | Advantages | Application Scenarios |

|---|---|---|

| Axial Piston | High torque output, suitable for low-speed operation | Heavy load, high-power equipment |

| Radial Piston | High efficiency, strong stability | Precision control, high performance |

| Gear | Simple structure, low maintenance cost | Medium and low-load applications, general machinery |

2. The Design of Hydraulic Motors and Its Impact on Precise Control

The design of hydraulic motors directly affects their performance and control precision. A well-designed hydraulic motor needs to take several factors into account, such as flow control, pressure regulation, system stability, and feedback mechanisms, all of which have a significant impact on precise control.

Key Elements of Precision Design

The design of a hydraulic motor must carefully consider the following aspects to ensure it provides precise power output and control in actual applications:

-

Flow Control: The flow rate and pressure of the hydraulic fluid directly affect the motor’s efficiency and stability. Precise flow control helps prevent system overloads and maintains stable motor output.

-

Pressure Regulation: The pressure in the hydraulic system must be kept within an optimal range. If the pressure is too high, it may lead to system failure or excessive wear; if too low, the motor’s performance will be impacted. Therefore, precise pressure regulation is crucial.

-

Low Friction Design: The internal friction in a hydraulic motor should be minimized to improve efficiency, reduce energy loss, and extend service life.

Control Systems and Feedback Mechanisms

Modern hydraulic motors are often paired with electronic control systems for precise speed and position control. By installing sensors and feedback mechanisms, hydraulic systems can continuously monitor and adjust flow, pressure, and other parameters to ensure each component operates precisely.

For example, in some precision machinery, the rotational speed and angle of hydraulic motors need to be precisely adjusted via digital control systems. This intelligent control enables hydraulic motors to be applied in various industries, enhancing overall system accuracy and automation.

3. Precise Control of Hydraulic Motors in Industrial Applications

The precise control of hydraulic motors makes them widely applicable across multiple industries, especially in equipment that requires high loads and high-precision tasks. Below, we’ll discuss some typical application scenarios.

Construction Machinery

In the construction machinery industry, hydraulic motors are widely used in excavators, cranes, and road rollers. These machines require hydraulic motors to provide high torque and stable power output while also needing precise control of movement speed and operational accuracy.

- Stability under High Loads: Hydraulic motors can provide smooth output even under heavy load conditions, ensuring stable equipment operation.

- Fine Control: Hydraulic systems in construction machinery allow for precise adjustment of power output, enabling operators to control the machine’s movements accurately.

Automation and Robotics

In automated production lines and industrial robots, hydraulic motors play an important role as well. When combined with PLC control systems, hydraulic motors can precisely control robotic movements, enabling highly accurate manufacturing processes.

- Precision Positioning: Hydraulic motors in robotics ensure precise positioning during tasks.

- High Efficiency: Automated equipment requires high power and accuracy, and hydraulic motors can deliver this performance.

Manufacturing and Machining

Hydraulic motors are used in CNC machines and automated assembly lines to provide stable power and precise control, ensuring machining accuracy and production efficiency.

- High Torque Output: Hydraulic motors provide powerful torque, supporting heavy-duty machining.

- Precision Control: Hydraulic motors enable fine-tuned adjustments for complex manufacturing processes, improving machining accuracy.

4. Advantages and Challenges of Hydraulic Motors

As a core driving component in industrial systems, hydraulic motors offer multiple advantages such as high torque output, high-temperature resistance, and easy adjustability. However, there are also some challenges that need to be addressed in practical applications.

Advantages of Hydraulic Motors

- High Torque Output: Hydraulic motors provide stable, high-torque performance, making them suitable for heavy-duty equipment and high-power applications.

- Easy to Control: Hydraulic systems can achieve precise control by adjusting flow and pressure, meeting the needs of different operating conditions.

- High Temperature Resistance: Hydraulic motors can operate stably under high-temperature environments, making them suitable for harsh conditions.

Challenges in Hydraulic Motor Applications

- Temperature Control: Excessive hydraulic oil temperature can affect the system’s performance, so temperature management solutions need to be considered in the design.

- System Leakage: Leakage in hydraulic systems can affect performance and safety, requiring optimized sealing designs and improved manufacturing precision.

- Maintenance Costs: Although hydraulic motors typically have long service lives, regular maintenance is still required, especially for hydraulic oil replacement and internal component inspection.

5. Future Development: More Intelligent Hydraulic Motor Control Systems

With the advent of Industry 4.0 and smart manufacturing, hydraulic motor control systems are evolving rapidly. Future hydraulic systems will be more intelligent, capable of dynamically adjusting operational parameters based on real-time needs, further improving operational efficiency.

Intelligent Control Technologies

With the development of sensor technologies, hydraulic motors will enable more precise real-time monitoring and adjustments. By using data analysis and machine learning algorithms, hydraulic motors can predict load changes and automatically optimize working conditions.

Unmanned and Automated Systems

In the future, hydraulic motors will play an increasingly important role in unmanned equipment. Autonomous heavy machinery and automated production lines will rely more on intelligent hydraulic control systems to improve production efficiency and safety.

ENG

ENG

English

English русский

русский Español

Español

English

English русский

русский Español

Español

TOP

TOP